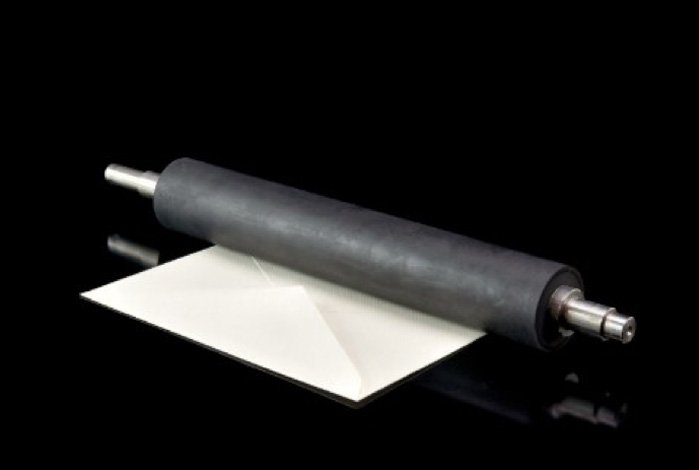

Our manufacturing partner specialises in the supply of precision customized parts in low to medium volumes in a wide range of materials. These include elastomeric covered rollers

Elastomers

Processes include

- Compounding – formulating personalised compounds

- Compression molding

- Injection molding

- Transfer molding

- Extrusions

- Casting

- Molecular adhesion

- Molding thermoplastics

- Hot air vulcanisation and steam autoclave

Materials available

- Natural rubber

- NBR (acrynitrile-butadiene)

- CR (chloroprene)

- EPDM (therpolymer of ethylene-propylene and diene)

- SBR (styrene-butadiene)

- VMQ (silicone – silicone rubber)

- PU Polyurethane (millable and cast polyurethane) AU EU

Finishing Processes

- Precision grinding

- Traditional grinding machines

- Semi-automatic

- CNC

Images Courtesy of Mussat

Steels and Plastics

Materials available

- Stainless steels in various grades

- Aluminium alloys

- AVP free cutting alloy steels

- Brass

- Copper

- Bronze

- Plastic resins

Manufacturing using wide range of equipment including

- CNC sliding head lathes with a capability of Ø2 to Ø35mm and milling machines

Special finishes available include

- Nickel plating (standard and chemical)

- Galvanising

- Anodising

- Cataphoresis (specialised organic coating method that uses electrical current to deposit paint onto a part or assembled product)

- Heat treatment

- Nitriding

- Hardening

Quality

The manufacturing process is supported by a dedicated quality control department with highly capable operators.

Equipment available

- Digital gauges

- Digital micrometers

- Calibrated pins

- Optical scanning systems

- Non-contact laser measuring devices

Images Courtesy of Tecnar SLR